About Yakult

What is Yakult?

Yakult is a probiotic fermented milk drink containing the unique Lacticaseibacillus paracasei Shirota (LcS) strain, which is exclusive to Yakult. This beneficial bacterium was named after Dr. Shirota, who first discovered the probiotic strain in 1930. Each 65ml bottle contains 6.5 billion of the LcS strain, meaning that every milliliter of Yakult contains 100 million (100,000,000) live LcS strain!

When Yakult is consumed as part of a healthy, balanced diet, the LcS strain has been shown to survive stomach acids and reach the intestines alive. It positively alters the balance of beneficial bacteria in the gut and encourages regular bowel movements by improving stool consistency.

Types of Yakult

Yakult Original & Yakult LIGHT are made fresh in our manufacturing plant in Dandenong South, Victoria, each sharing these unique qualities;

- Unique and beneficial probiotic bacteria Lacticaseibacillus paracasei Shirota strain

- 6.5 billion CFU in every 65mL bottle

- Low in lactose

- Shelf life of 45 days

- Fat & cholesterol free

- Gluten free

- Free from artificial colours & preservatives

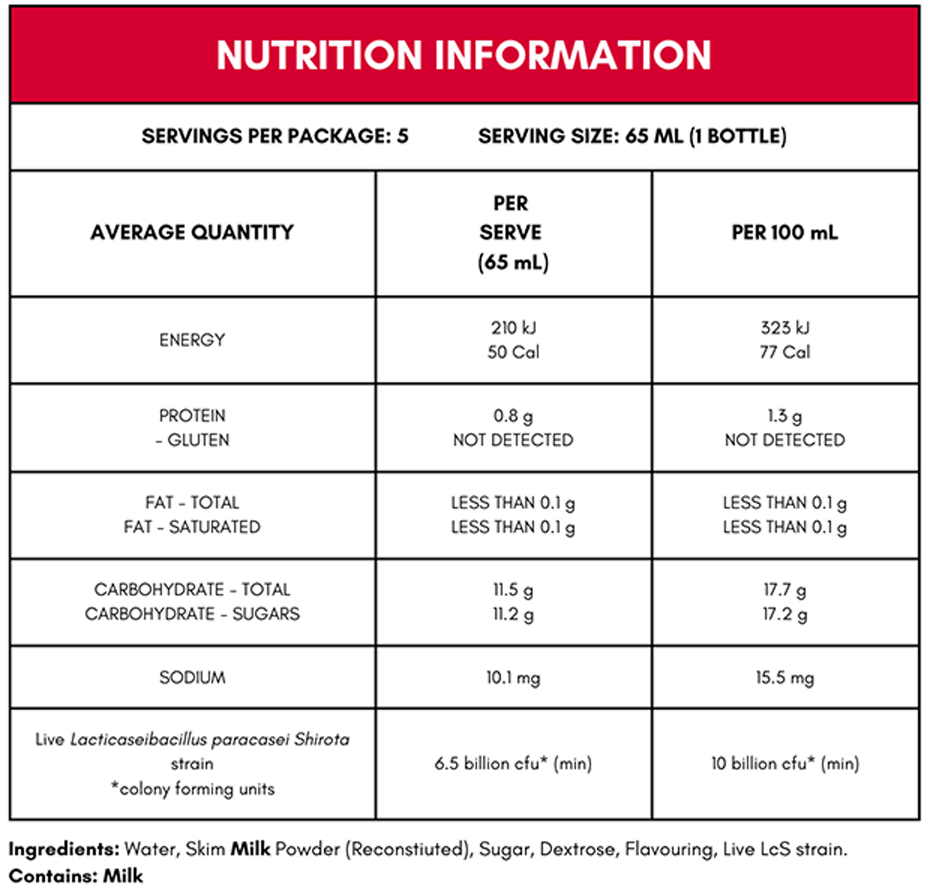

Yakult Original

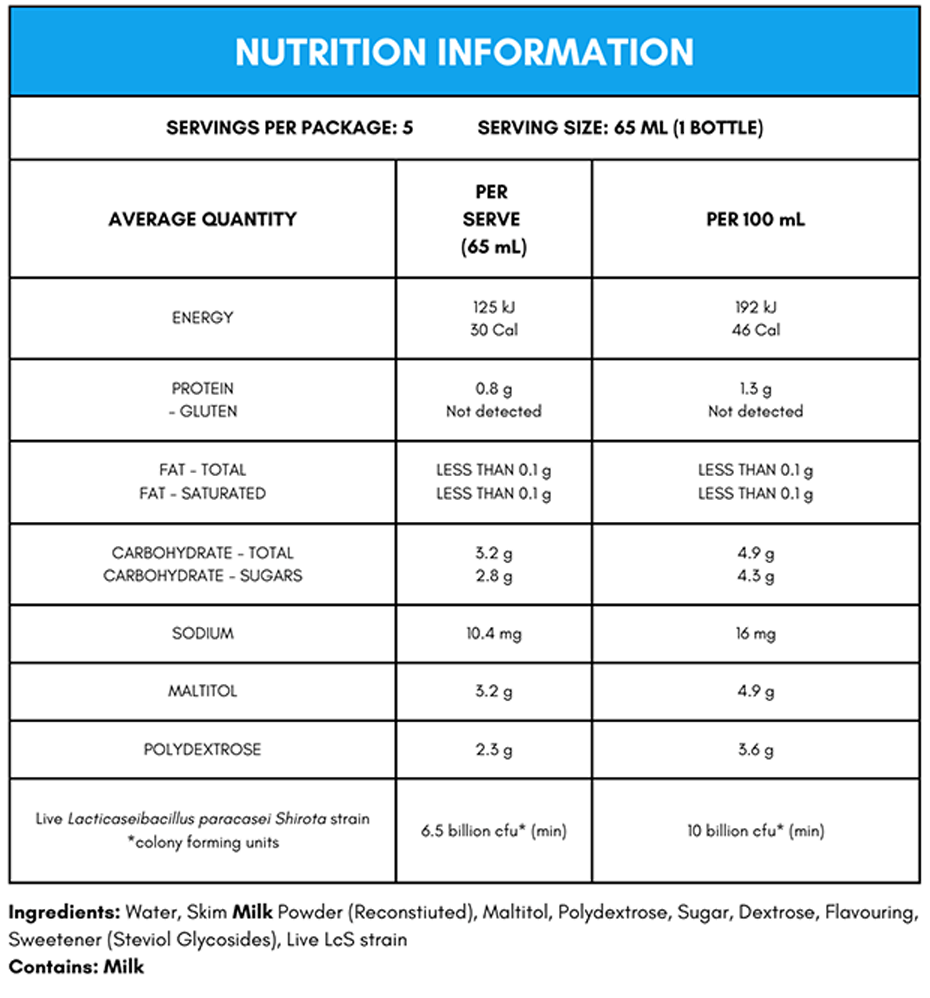

Yakult LIGHT

Yakult LIGHT contains 75% less sugar and 40% less calories than Yakult Original. We are using stevia, a plant-based sweetener, to replace some of the sugar used in Yakult to provide sweetness and maintain that great refreshing taste. Yakult LIGHT is currently available in a 5-bottle pack.

How is Yakult made?

The step-by-step production of Yakult

Yakult’s “purpose built” Australian factory is a technologically advanced manufacturing facility. It incorporates some of the latest food processing equipment. Strict standards apply to producing Yakult, ensuring a drink yield that is close to 99% (this means that 99% of the raw ingredients end up in the bottle). There are no by-products and little waste. The Yakult factory is based in Dandenong, Victoria and makes Yakult for the whole of Australia and New Zealand.

Yakult Production

Step 1

Dissolving raw ingredients

Water used is filtered by reverse osmosis to remove trace minerals, which is then sterilised using ultraviolet light and stored in a large holding tank before being used in the production process.

Skim milk powder, sugar and dextrose are mixed with filtered water to make a milk solution.

Step 2

Sterilisation

The milk solution is sterilised at a high temperature (above 100°C) for a short time, destroying any bacteria that may be present. This process is called HTST (High Temperature, Short Time).

Step 3

Fermentation

The milk solution is transferred via a closed system of pipes and valves to a fermentation tank where the temperature is decreased to an appropriate level. A starter culture of the Lacticaseibacillus paracasei Shirota strain is inoculated into the milk solution. The bacteria multiplies during the fermentation process.

Step 4

Homogenisation

After the fermentation period, the milk solution undergoes a process known as homogenisation. The fermented milk is placed under high pressure while passing through a structure with small holes creating a smooth consistency.

Step 5

Blending, Mixing and Storage

The fermented milk solution is blended with a unique flavour and is transferred to a large storage tank containing chilled sugar syrup.

Step 6

Dilution

Prior to bottling, the concentrate is diluted with filtered, sterilised water

Bottle Making

Step 7

Injection Blow Moulding Machine

Yakult’s unique-shaped plastic bottles are produced on-site from triple food grade polystyrene code 6 recyclable pellets using injection blow-moulding machines.

Step 8

Bottle Storage Tank

Air pressure transports the empty bottles to the bottle storage tanks that are capable of holding one million bottles.

Filling and Packaging

Step 9

Bottle Selector

Empty bottles are released from the bottle storage tank into a large circular selector which places the bottles in an upright position before being fed onto the filling line.

Step 10

Printing Station

Bottles move along the conveyor belt to the printing station where the name “Yakult” and the appropriate labelling information are printed on the bottle in an instant-drying, red ink. Yakult LIGHT has a pre-printed sleeve placed around the bottle which is individually cut and heat shrunk onto the empty bottle. A use-by date ink is printed on the curved waist of the bottle.

Step 11

Filling, Capping & Sealing Machine

Bottles are filled with 65ml of fresh Yakult, capped with a foil lid, sealed and transferred along the conveyor belt to the packaging facility.

Step 12

Control Panel

This machine is fully computerised and controls the flow of production. Different coloured lights indicate any areas that need attention.

Step 13

Shrink-Wrap & Packaging Machine

Single bottles of Yakult are sorted into groups of five or ten and shrink-wrapped. 5 x ten packs or 10 x five packs are grouped together, wrapped in film and then heat shrunk, forming a “slab” of 50 Yakult bottles.

Step 14

Finished Product

Distribution

Step 15

Robotic Arm

Slabs are then transferred on to a pallet by our robotic arm. The stacked pallet is wrapped and transported to the cold storage facility.

Step 16

Cold Storage facility

Pallets are stored at a temperature of 2-3°C whilst awaiting delivery to the stores in our cold storage facility. An energy and space efficient storage method is used in the facility.

Step 17

Distribution

Refrigerated trucks deliver Yakult to the warehouses of the major supermarket chains (e.g. Woolworths and Coles) for distribution to individual supermarkets. Yakult is delivered directly to independent supermarkets, milk bars, schools, hotels, aged care centres, hospitals and other outlets by our sales consultants.

Product Management

Step 18

Yakult Quality Management

Yakult maintains a comprehensive Quality Management Program in order to ensure that our product is of the highest quality. For this reason, samples are collected for laboratory analysis throughout the production process to confirm that the quality assurance measures in place have been effective.

Yakult testing involves more than 120 samples per production run, upon which a total of more than 100 tests are conducted. These determine Lacticaseibacillus paracasei numbers, check for potential contaminants, microbiological quality, composition, acidity, physical attributes and taste. In addition, each bottle is inspected for undesirable markings and incorrect printing.

Quality assurance measures are in place to maintain standards for personnel and factory hygiene, equipment cleaning, processing methods and parameters, and product handling. Yakult’s quality assurance utilises a system called “Hazard Analysis and Critical Control Points” (HACCP). The principles of HACCP are internationally recognised as an excellent method for assuring stringently high standards.

Step 19

Waste Management

Cleaning. Yakult adheres to a comprehensive hygiene and sanitation program, following a cleaning program that is predominantly governed by CIP (Cleaning in Place). Steam, an environmentally friendly cleaner, is used to sterilise the pipes and tanks. A single phase chemical cleaner is used, reducing the numbers of chemicals introduced into the drains, chlorine-based chemicals are not used.

Solid wastes. The amount of solid waste is relatively small, and a number of measures are made to reduce waste. Recycling occurs where it is economically and environmentally viable. Paper products (skim milk powder bags, etc.) are recycled. The bottles are crushed and mixed with other resin to be made into a variety of plastic products, e.g. chairs and tables.

Liquid wastes. Any liquid waste goes into a holding tank in our water treatment facility. The acidity (pH) of the water is adjusted with acid or alkaline to meet Melbourne Water standards before being released into the sewage system.

Step 20

Energy Management

Yakult has a commitment to using energy efficiently and wisely for sound environmental and economic reasons. The factory incorporates the latest equipment and techniques to reduce the amount of energy used. For example:

- All fluids are heated using heat exchange plates.

- All machinery is well maintained to function optimally, ensuring energy is not lost or wasted.

- No CFC’s are used in cooling or refrigeration.

- Off peak rates are used for utilities whenever possible. For example, the ice bank water storage keeps all water at 0°C using compressors that are run in the evenings, during off peak rates.

- Our boiler uses natural gas and is run for short periods as required (therefore no pollution is emitted).

- Longer lasting and mercury-free LED lighting have replaced all florescent lighting in our manufacturing plant and head office, helping to reduce the demands we make on the planet, and our energy consumption.